Coal Inspectorate | Alert | No.405 V 1 | 14 March 2022

Failure of goaf well skid safety system

What happened?

On 10 March 2022, a severe weather event occurred in the regional areas of Moranbah. Records have identified that between 4pm and 8pm, 852 cloud to ground lightning strikes occurred in the region.

Lightning is believed to have struck one or more of three goaf gas blower skids, igniting the gas on one of them. The gas burned at the top of the evasee for an unknown period of time before being discovered by a seam gas operator who applied an emergency shutdown of the plant.

The three goaf gas blower skids were in close proximity to each other and were operating on a sealed goaf at the time of the incident.

The goaf gas blower skid was on free vent at the time of the incident, operating at approximately 156lt/sec.

The plant was running high purity of 100% methane and nil oxygen.

A mine evacuation was ordered and the plant scene was secured.

How did it happen?

A severe weather event occurred with multiple lightning strikes at the surface of an underground mine.

Goaf gas blower skids have earthing protection, Flame arrestor and detonation arrestors, by design, do not have lightning protection.

Key issues

- Initial investigation identified the plant that had the fire had not lost gas pressure to the fusible plugs in place for the flame arrestor and the secondary fusible plug for the detonation arrestor.

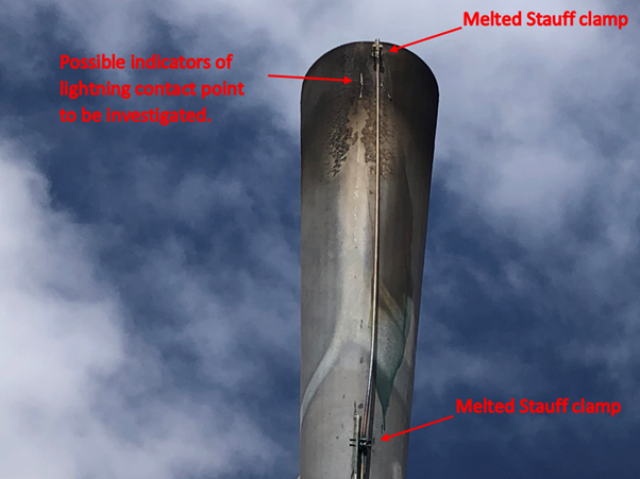

- It was identified that the goaf gas blower skid that was on fire at the evasee and the fusible plug close to the exit point of the evasee had burnt and should have activated. Two Stauff clamps on the steel fusible plug tube line melted, which was believed to be as a result of the lightning strike.

- A blockage in the tube running from the fusible plug to the flame arrestor - gas cylinder. The product blocking the pipe is still to be identified.

- Two other goaf gas blower skids in close proximity were identified to have possibly received a lightning strike and the Stauff clamps close to the top of the evasee outlet were melted. One plant was shutdown by activation of a fusible plug. The other was still free venting. Both were approximately 30lt/sec each.

Recommendations

All site senior executives should:

- Inspect all surface to inseam gas drainage plant for functionality of safety devices.

- Check the maintenance regime for gas drainage systems to ensure safety circuit systems are tested for activation.

- Check the tube system for fusible plugs to ensure they are clear and free of material that may cause blockage.

The mine where this incident has occurred has added withdrawal from the mine to their lightning TARP triggers while the investigation is ongoing.

Investigations are ongoing and further information may be published as it becomes available. The information in this publication is what is known at the time of writing.

We issue Safety Notices to draw attention to the occurrence of a serious incident, raise awareness of risks, and prompt assessment of your existing controls.

Contact: Paul Brown, Inspector of Mines , +61 7 3199 8001 QldMinesInspectorate@rshq.qld.gov.au

Issued by Resources Safety & Health Queensland

Placement: Place this announcement on noticeboards and ensure all relevant people in your organisation receive a copy, understand the content, findings and recommendations as applicable to their operation. SSEs should validate that recommendations have been implemented.

Find more safety notices

Search the hazards database